hardness test standards pdf|astm rockwell hardness chart : advice This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials. It is applicable to both fixed location and portable hardness testing machines.

WEBMañana es hoy. 2022. Nacho G. Velilla. Javier Gutiérrez, Carmen Machi, Asier Rikarte, Silvia Abril . 4,8. 5.990. Comedia Verano de 1991. La familia Gaspar comienza sus vacaciones en la playa pero, tras discutir con su padre, Lucía, la hija adolescente, decide fugarse con su novio. Una tormenta eléctrica pilla al resto de la familia a .

{plog:ftitle_list}

When you sign in to your account, you can see your payment info, transactions, recurring payments, and reservations

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness prin-ciple. This .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .The revision of E 18 requires that all performance verifications of Rockwell hardness indenters and hardness machines must be made using test blocks calibrated traceable to the Rockwell .Metallic materials — Rockwell hardness test — Part 1: Test method (scales A, B, C, D, E, F, G, H, K, N, T) 1 Scope This part of ISO 6508 specifies the method for Rockwell and Rockwell .

Listed below are common American Society for Testing and Materials (ASTM) .This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials. It is applicable to both fixed location and portable hardness testing machines.The procedure for determining indentation hardness of substances classified as thermoplastic elastomers, vulcanized (thermoset) rubber, elas-tomeric materials, cellular materials, gel-like .

3.1.4 Rockwell hardness test an indentation hardness test using a veriÞed machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter, .Metallic materials — Rockwell hardness test — Part 1: Test method 1 Scope This part of ISO 6508 specifies the method for Rockwell regular and Rockwell superficial hardness tests .Hardness is the most commonly used industrial test for quality control and acceptance testing of metals and metallic products. Of over 12 000 ASTM standards, hardness test method .

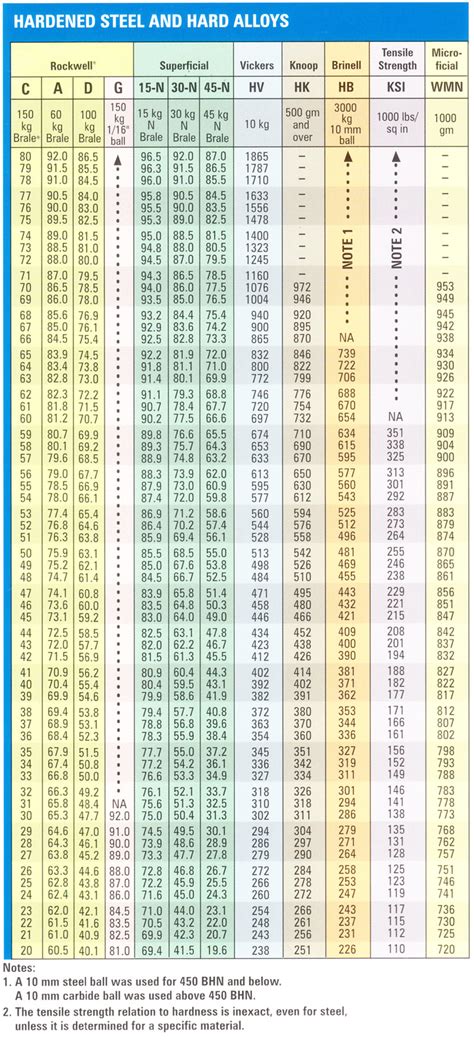

rockwell hardness testing chart

ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .Standardization of Brinell Hardness Test Blocks Annex A4 1.3 This standard includes nonmandatory information in an appendix which relates to the Brinell hardness test: Table of Brinell Hardness Numbers Appendix X1 Examples of Procedures for Determining Brinell Hardness Uncertainty Appendix X2 1.4 At the time the Brinell hardness test was .Indian Standard METHOD FOR VICKERS HARDNESS TEST FOR METALLIC MATERIALS ( Third Revision) Ics 77.040.10 0 61s 2002 BUREAU OF INDIAN STANDARDS MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG NEW DELHI 110002 October 2002 Price f% 600.00 L, Mechanical Testing of Metals Sectional Committee, MTD 3

ISO 6506-3:2014, Metallic materials — Brinell hardness test — Part 3: Calibration of reference blocks ISO 6506-4, Metallic materials — Brinell hardness test — Part 4: Table of hardness values 3 Principle An indenter (tungsten carbide composite ball with diameter, D) is forced into the surface of a test pieceThe Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .

hand held refractometers nz

Standard Test Method for Leeb Hardness Testing of Steel Products1 This standard is issued under the fixed designationA956/A956M; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.Designation: E 92 – 82 (Reapproved 2003) An American National Standard Standard Test Method for Vickers Hardness of Metallic Materials1 This standard is issued under the fixed designation E 92; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. Standard Test Method for Film Hardness by Pencil Test D3363-22 ASTM|D3363-22|en-US Standard Test Method for Film Hardness by Pencil Test Standard D3363 Standard Test Method for Film Hardness by Pencil Test> new BOS Vol. 06.01 Committee D01 . (PDF) format to Licensee and its Authorized Users, who are solely responsible for installing and .For specific materials and/or products, other specific International Standards apply (for instance, ISO 3738‑1 and ISO 4498). NOTE Attention is drawn to the fact that the use of tungsten carbide composite for ball indenters is considered to be the standard type of Rockwell indenter ball.

E691 Practice for Conducting an Interlaboratory Study to 3.2.2 microindentation hardness test, n—a hardness test, Determine the Precision of a Test Method 3 normally in the Vickers or Knoop scales, using test forces in 2.2 ISO Standards: the range of .E92-23 Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials . E2546-15(2023) Standard Practice for Instrumented Indentation Testing . E18-24 Standard Test Methods for Rockwell Hardness of Metallic Materials .ISO 6508-2:2015(E) 4.3.2 The instrument or gauge blocks used to verify the depth-measuring system shall have a maximum expanded uncertainty of 0,000 3 mm when calculated with a 95 % confidence level. 4.3.3 Calibrate the testing machine’s depth measurement system at not less than four evenly spaced increments covering the full range of the normal working depth .

Institute (NMI) for hardness, and as such, is responsible for traceability in hardness measurements. Objective Impact and Customers • Hardness is the most commonly used industrial test for quality control and acceptance testing of metals and metallic products. • Of over 12 000 ASTM standards, hardness test method standards are

The Vickers hardness number, in terms of gf and µm, is calculated as follows: 5.7 Test Forces—The standard hardness test forces are given in Table 1. Other non-standard test forces may be used by special agreement.Indian Standard METHOD FOR BRINELL HARDNESS TEST FOR METALLIC MATERIALS ( Third Revision) 1 Scope This part of ISO 6506 specifies the method for the Brinell hardness test for metallic materials and is applicable up to the limit of 650 HBW. For specific materials and/or products, particular International Standards exist (i.e. ISO 4498-l).block of a hardness equal to or greater than the maximum expected hardness of the material being tested, and one calibration block near the middle of the range should be used. 9. Procedure 9.1 Test Method—To perform a hardness test, the impact device is connected to the indicator device and the instrument is turned on.Wilson Hardness test blocks set the standard for the industry and are made from the highest quality material to insure the most uniform and repeatable blocks available. A comprehensive variety of scales and blocks are available to meet the wide ranges and hardness scales associated with Rockwell®, Brinell, Knoop and Vickers testing.

test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), and 150 kgf (1471 N). 1.5 Units— At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the units of force and length in the International System of Units (SI); that is, force in Newtons (N) and length in millimeters (mm).

ISO 6508-2, Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters ISO 6508-3, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Terms and definitions No terms and definitions are listed in .‘carbonate hardness’ and the amount of hardness in excess of this is called ‘non-carbonate hardness’. Some waters containing high concentrations of borates, phosphates, silicates, may contribute to total alkalinity. There is no ISO Standard on the subject. The first revision of this standard was published in 1983 by superseding 16

5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average .

2.Test step The additional test force is then applied for a dwell time (several seconds) defined according to the standard, whereby the indenter penetrates the specimen to the maximum penetration depth h1. The sum of the test preload and additional test force is the total test force (also referred to as total force or main load). 3.Test step

Standard Test Method for Rubber Property—Durometer Hardness1 This standard is issued under the fixed designation D2240; the number immediately following the designation indicates the year of . 3.1 This test method permits hardness measurements based on either initial indentation or indentation after a specified period of time, or both .At lower test loads the Vickers hardness may be load-dependent. In Table 2 are given the Vickers hardness numbers for a test load of 1 kgf. For obtaining hardness numbers when other test loads are used, the Vickers hardness number obtained from Table 2 is multiplied by the test load in kilograms-force (Table 3). 1.obtained from the AWS Welding Handbook, Ninth Edition, Volume 1, which describes selected weldability test methods. AWS B4.0:2016, Standard Methods for the Mechanical Testing of Welds, is the eighth edition of the document initially published in 1942. . hardness testing and stud weld tests, and organized the tests by weld type. The sixth .

rockwell hardness tester diagram

The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is .

hand refractometer adalah

hand refractometer atago

WEBMañana es hoy: Egy család 1991-ben nyaral, amikor tizenéves lányuk úgy dönt, hogy megszökik a barátjával. A szülők előre utaznak az időben 2022-be, és meglátják, mennyit változott Spanyolország három évtized alatt. .

hardness test standards pdf|astm rockwell hardness chart